304 Stainless Steel Plate

Stainless Steel Plate

Grade: 300 series

Standard: ASTM

Length: Custom

Thickness: 0.3-3mm

Width: 1219 or custom

Origin: Tianjin, China

Brand name: zhongao

Model: stainless steel plate

Type: sheet, sheet

Application: dyeing and decoration of buildings, ships and railways

Tolerance: ± 5%

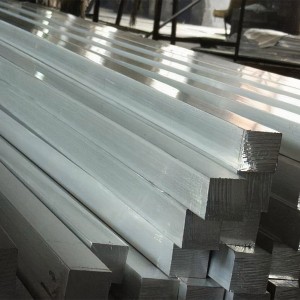

Processing services: bending, welding, uncoiling, punching and cutting

Steel grade: 301L, s30815, 301, 304n, 310S, s32305, 410, 204c3, 316Ti, 316L, 34,14j 321, 410S, 410L, 436l, 443, LH, L1, s32304, 314, 347, 430, 309S, 304, 439, 204c2, 425m, 409L, 4, 5, 30L, 4, 5, 30j2 444, 301LN, 305, 429, 304j1, 317L

Surface treatment: BA

Delivery time: 8-14

Product Name: 304 stainless steel plate

Process: cold rolling and hot rolling

Surface: Ba, 2b, No.1, no.4,8k, HL,

Mirror edge: grinding and trimming

Packaging: PVC film + waterproof paper + fumigation wood frame

Sample: free sample

304 stainless steel is a general steel with good corrosion resistance. Its thermal conductivity is better than that of austenite, its coefficient of thermal expansion is smaller than that of austenite, heat fatigue resistance, addition of stabilizing element titanium, and good mechanical properties at the weld. 304 stainless steel is used for building decoration, fuel burner parts, household appliances and household appliances 304F is a kind of steel with free cutting performance on 304 steel. It is mainly used for automatic lathes, bolts and nuts. 304lx adds Ti or Nb to 304 steel and reduces the content of C, which improves the processability and welding performance. It is mainly used in hot water tank, hot water supply system, sanitary ware, household durable appliances, bicycle flywheel, etc.

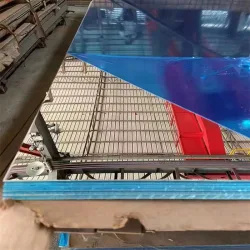

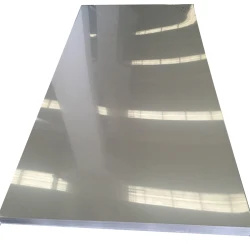

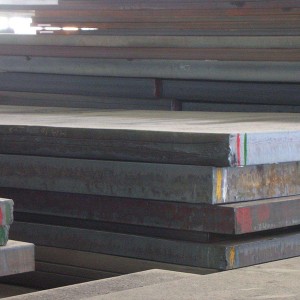

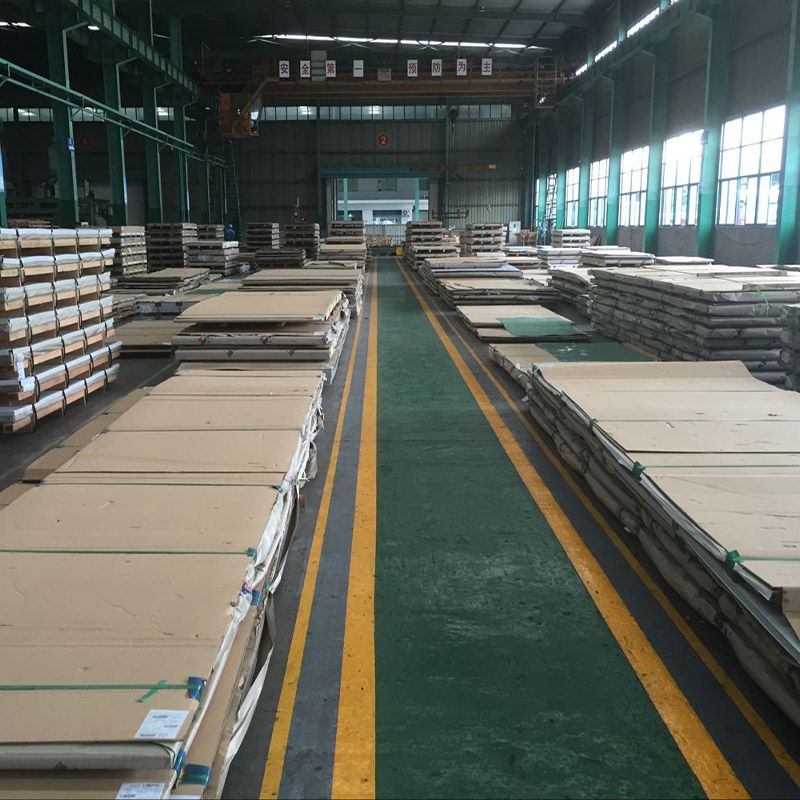

Product Display

Classification And Process

Surface grade

304 stainless steel has the following states. Different states, dirt resistance and corrosion resistance are also different.

No.1, 1D, 2D, 2b, N0.4, HL, Ba, mirror, and various other surface treatment states.

Characteristic processing technology

1D - discontinuous granular surface, also known as fog surface. Processing technology: hot rolling + annealing, shot peening and pickling + cold rolling + annealing and pickling.

2D - slightly shiny silver white. Processing technology: hot rolling + annealing, shot peening and pickling + cold rolling + annealing and pickling.

2B - silvery white and better gloss and flatness than 2D surface. Processing technology: hot rolling + annealing, shot peening and pickling + cold rolling + annealing and pickling + quenching and tempering rolling.

BA - excellent surface gloss and high reflectivity, just like the surface of a mirror. Processing technology: hot rolling + annealing, shot peening and pickling + cold rolling + annealing and pickling + surface polishing + quenching and tempering rolling.

NO.3 - it has good gloss and coarse grain on the surface. Processing technology: polishing and quenching and tempering rolling of 2D products or 2B with 100 ~ 120 abrasive materials (JIS R6002).

NO.4 - it has good gloss and fine lines on the surface. Processing technology: polishing and quenching and tempering rolling of 2D or 2B with 150 ~ 180 abrasive material (JIS R6002).

HL - silver gray with hair stripes. Processing technology: Polish 2D or 2B products with abrasive materials with appropriate particle size to make the surface show continuous grinding lines.

Mirro - mirror state. Processing technology: grind and polish 2D or 2B products with appropriate particle size grinding materials to the mirror effect.

Material Properties

304 stainless steel has the ability of oxidation resistance to corrosion, but has the tendency of intergranular corrosion.

304 stainless steel wire is widely used in axis.

Because it is safe and non-toxic, it is widely used in food tableware.

Common Species

austenite

301, 302, 303, 303se, 304, 304L, 304N1, 304N2, 304LN, 305, 309S, 310S, 316, 316L, 316N, 316J1, 316J1L, 317, 317L, 317J1, 321, 347, XM7, XM15J1, 329J1

Ferrite

405, 430, 430F, 434, 447J1, 403

Martensite

410, 410L, 405, 416, 410J1, 420J1, 420J2, 420F, 431, 440A, 440B, 440C, 440F, 630, 631, 632

There is also a kind of stainless steel, 201, 202, 203 and 204, which has low chromium and high manganese (high chromium energy increases corrosion resistance, and high manganese can make the material non-magnetic). This kind of stainless steel has poor corrosion resistance and is generally used for dry environment decoration.

By Surface Feature

| Surface | Features | Summary of manufacturing methods | Purpose |

| NO.1 | Silvery white Matte | Hot rolled to specified thickness | Use without surface gloss |

| NO.2D | Silvery white | Heat treatment and pickling after cold rolling | General material, deep drawing material |

| NO.2B | Gloss stronger than No.2D | After No.2D treatment, the final light cold rolling is carried out through the polishing roller | General timber |

| BA | Bright as a mirror | There is no standard, but it is usually bright annealed surface processing, with high surface reflectance. | Building materials, kitchen utensils |

| NO.3 | Rough grinding | Grind with 100 ~ 200# (unit) abrasive belt | Building materials, kitchen utensils |

| NO.4 | Intermediate grinding | A polished surface obtained by grinding with 150~180# abrasive tape | Ditto |

| NO.240 | Fine grinding | Grinding with 240# abrasive belt | kitchenware |

| NO.320 | Very fine grinding | Grinding with 320# abrasive belt | Ditto |

| NO.400 | Gloss close to ba | Grind with 400# polishing wheel | General materials, building materials, kitchen utensils |

| HL | Hair line grinding | There are a lot of grinding particles in hair line grinding (150 ~ 240#) with appropriate particle materials | Building materials |

| NO.7 | Close to mirror grinding | Grinding with 600# rotary polishing wheel | For art and decoration |

| NO.8 | Mirror grinding | The mirror is ground with a polishing wheel | Reflector, decorative |