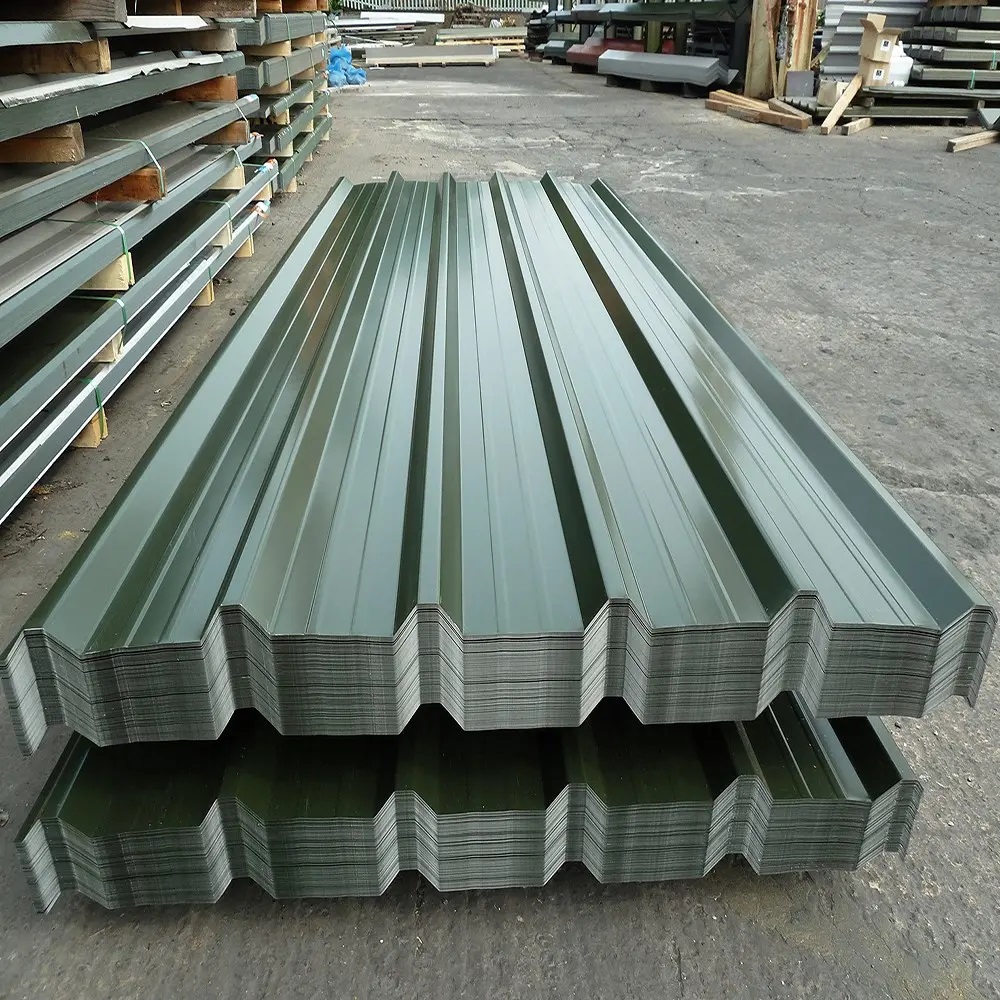

Color steel tile price

Structural Components

Origin: Shandong, China

Brand name: zhongao

Application: making corrugated board

Type: steel coil

Thickness: 0.12 to 4.0

Width: 1001-1250 - mm

Certificates: BIS, ISO9001, ISO,SGS,SAI

Level: SGCC/CGCC/DX51D

Coating: Z181 - Z275

Technology: Based on hot rolling

Tolerance: + / - 10%

Sequins type: Common sequins

Oiled or unoiled: Lightly oiled

Hardness: full hard

Delivery time :15-21 days

Zinc coating: 30-600g/m2

Coil weight: 3-5 tons or as required

Coil ID: 508 mm / 610 mm

Terms of payment: T/T,L/C, Kunlun Bank,

Minimum order quantity: 25MT (one 20ft FCL)

Delivery time: within 15-20 days

Standard: ASTMA36 JISG3302

Steel coil, also known as coil steel. The steel is rolled by hot pressing and cold pressing. In order to facilitate storage and transportation, facilitate various processing (such as processing into steel plate, strip, etc.)

The pattern coil is also known as the pattern steel plate, is its surface with a diamond or protruding steel plate.

Because of the protruding edge on the surface of the decorative steel plate, it can be used as floor, factory escalator, working frame pedal, ship deck, car bottom plate, etc.

The specifications of the pattern steel plate are expressed in terms of basic thickness (excluding the thickness of the protruding edge), with 10 specifications of 2.5-8 mm. Patterned plate plates are numbered 1-3.

Product Introduction

Forming coil is mainly hot rolled coil and cold rolled coil. Hot rolled coil is the processed product before recrystallization of billet. Cold rolled coil is the follow-up processing of hot rolled coil. The general weight of steel coil is about 15-30T. China's hot rolling production capacity is expanding, there have been dozens of hot rolling production lines, and some projects will be built or put into operation.

General users do not have uncoiling equipment or limited amount. Therefore, the subsequent processing of steel coil will be a very promising industry. Of course, at present the larger steel mills have their own unwinding and leveling projects.

Surface quality is divided into two levels:

Normal accuracy: thin oxide sheet, rust, rough surface due to the peeling off of oxide sheet and other local defects whose height or depth exceeds the allowable deviation are allowed on the surface of the steel plate.

product display