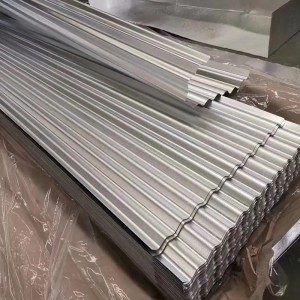

House color steel tile

Concept

From finishing the last hot steel strip mill out through laminar flow cooling to the set temperature, which consists of the winder coil, steel coil after cooling, according to the different needs of users, with different finishing line (flat, straightening, transverse or longitudinal cutting, inspection, weighing, packaging and logo, etc.) and become a steel plate, flat roll and longitudinal cutting steel strip products.

Material Q235B, Q345B, SPHC, 510L, Q345A, Q345E

It is suitable for industrial and civil buildings, warehouses, special buildings, large span steel structure house roof, wall and inner and outer wall decoration, with light weight, high strength, rich color, convenient construction, seismic, fire, rain, long life, maintenance free and other characteristics, has been widely promoted and applied.

Color steel coil is a kind of composite material, also known as color coated steel plate is made of strip steel in the production line after continuous surface degreasing, phosphating and other chemical transfer coating treatment, coated with organic coating by baking products.

Color coil is a kind of composite material, both steel plate and organic materials. Not only the mechanical strength of steel plate and easy molding performance, but also the good decorative organic materials, corrosion resistance.

Color coil coating types can be divided into: polyester (PE), silicon modified polyester (SMP), polyvinylidene fluoride (PVDF), high weather resistance polyester (HDP), clinker sol.

Color steel materials are divided into five categories: packaging, home appliances, building materials, optical materials and decorative materials. Among them, home appliances color steel material technology is the best and the most fine, the highest production requirements.

Other Industries

Other industrial applications are bicycle parts, various welded pipes, electrical cabinets, highway guardrail, supermarket shelves, warehouse shelves, fences, water heater liner, barrel making, iron ladder and stamping parts of various shapes. With the continuous development of economy, zero processing throughout the industry, the rapid development of processing plants mushrooming, the demand for plate greatly increased, but also increased the potential demand for hot rolled pickling plate.

Anticorrosive tile is the preferred building material for chemical industry plants. What are the specific advantages of anticorrosive tile in chemical plants? Let's take a look.

1) Corrosion prevention:

Anti-corrosion tile is not easy to be acid and alkali corrosion, unlike iron tiles and other materials only in the outer layer to do processing, but from the nature of chemical corrosion. Excellent corrosion resistance is the best choice of chemical plant roofing materials.

2) Strength and toughness:

Impact resistance, tensile resistance, not easy to crack. In the case of 660mm support span, the loading load is 150kg. Tiles do not crack and damage.

3) Weather resistance:

Due to the addition of UV anti-uv agent in the material, it can really play an anti-uv irradiation. It solves the weather resistance problem of ordinary plastics, and the service life of anticorrosive tile is 3 times of ordinary metal products.

4) Low noise:

When it rains, the noise is more than 30dB lower than that of metal roofing panels including color steel tiles. In the event of rain or inclement weather, noise disturbance and impact can be reduced.

5) No rust:

Anticorrosive tile itself does not rust, and the color is bright and beautiful. It avoids the problem of rust stains caused by corrosion.

product display