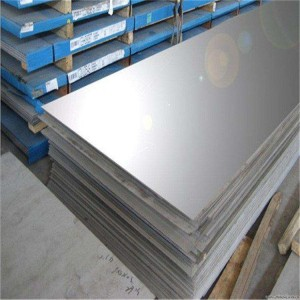

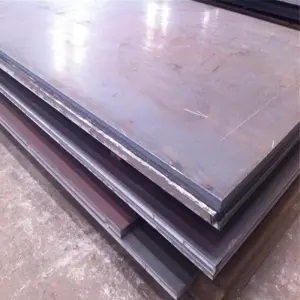

Stainless Steel Plate High Nickel Alloy 1.4876 Corrosion Resistant Alloy

Introduction To Corrosion Resistant Alloys

1.4876 is a Fe Ni Cr based solid solution strengthened deformed high temperature corrosion resistant alloy. It is used below 1000 ℃. 1.4876 corrosion resistant alloy has excellent high temperature corrosion resistance and good process performance, good microstructure stability, good processing and welding performance. It is easy to form by cold and hot processing. It is suitable for making parts that require high temperature and long-time work under harsh corrosive medium conditions.

Corrosion Resistant Alloy Properties

1.4876 corrosion resistant alloy has good stress corrosion crack resistance, stress corrosion crack resistance in water chloride, corrosion resistance to steam, air and carbon dioxide mixture, and good corrosion resistance to organic acids such as HNO3, HCOOH, CH3COOH and propionic acid.

Executive Standard For Corrosion Resistant Alloys

1.4876 corrosion resistant alloy executive standards there are a series of standards in various countries. Foreign standards are generally UNS, ASTM, AISI and din, while our national standards include brand standard GB / t15007, rod standard GB / t15008, plate standard GB / t15009, pipe standard GB / t15011 and belt standard GB / t15012.

Corresponding Brand Of Corrosion Resistant Alloy

German standard: 1.4876, x10nicralti32-20, American Standard no8800, 1.4876, national standard gh1180, ns111, 0cr20ni32fe

Chemical Composition Of Corrosion Resistant Alloy

Carbon C: ≤ 0.10, silicon Si: ≤ 1.0, manganese Mn: ≤ 1.50, chromium Cr: 19 ~ 23, nickel Ni: 30.0 ~ 35.0, aluminum al: ≤ 0.15 ~ 0.6, titanium Ti: ≤ 0.15 ~ 0.6, copper Cu: ≤ 0.75, phosphorus P: ≤ 0.030, sulfur s: ≤ 0.015, iron Fe: 0.15 ~ surplus.

Corrosion Resistant Alloy Processing And Welding

1.4876 corrosion resistant alloy has good hot working performance. The hot working temperature is 900 ~ 1200 and the hot bending forming is 1000 ~ 1150 degrees. In order to reduce the intergranular corrosion tendency of the alloy, it should pass through the 540 ~ 760 degree sensitization zone as quickly as possible. Intermediate softening annealing is required during cold working. The heat treatment temperature is 920 ~ 980. The solid solution temperature is 1150 ~ 1205. The welding condition is good, and the conventional welding method.

Physical Properties Of Corrosion Resistant Alloys

Density: 8.0g/cm3, melting point: 1350 ~ 1400 ℃, specific heat capacity: 500J / kg. K, resistivity: 0.93, elastic modulus: 200MPa.

Application Field Of Corrosion Resistant Alloy

1.4876 corrosion resistant alloy has excellent stress corrosion resistance in water containing chloride and low concentration NaOH. It is widely used to manufacture stress corrosion-resistant equipment instead of 18-8 austenitic steel. It is used in pressure water reactor evaporator, high temperature gas cooled reactor, sodium cooled fast reactor heat exchanger and superheated steam pipe in power industry. It is used in HNO3 cooler, acetic anhydride cracking pipe and various heat exchange equipment in chemical industry.